Need to know more about the different construction sectors? Knowing the 4 major construction sectors, how they differ, and the required ventilation systems will help you better understand the construction field.

elearning-training.com gathered defining information about the 4 sectors of construction and how air conditioning and heating differ in each sector.

Sectors of Construction

Construction plans and projects can be commissioned publicly, by municipal agencies, or privately. Projects like bridges, highways, pipelines, residential structures, or facilities like hospitals and stadiums fall under one of the four construction sectors. To better understand the various types of project classifications in the construction industry, consider the following:

1. The Residential Construction Sector

Residential construction is building, remodeling, repairing, building (ground up), or modifying the structure’s interior or exterior. Residential construction refers to buildings meant to “house” people, equipment, or supplies.

Typically, those new to the construction industry assume residential construction refers only to homes and buildings for people. However, a residential building can also include garages and utility sheds. This construction sector also addresses installing electricity and wiring, plumbing, sewage systems, and pavement.

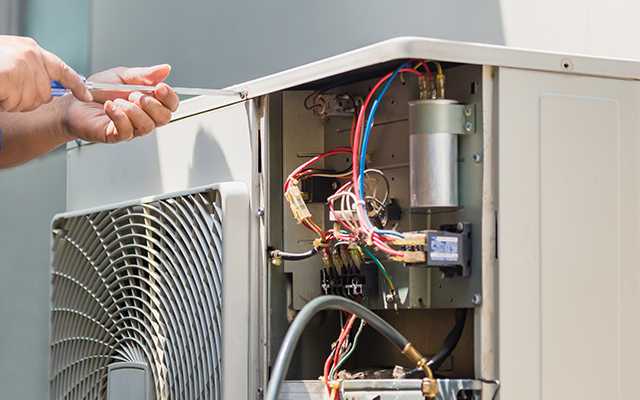

Residential HVAC: HVAC (heating, ventilation, and air conditioning) systems are responsible for heating and cooling your home and can include:

- Furnaces

- Air Conditioners

- Heat Pumps

- Ductwork

- Thermostats

Note: A residential HVAC unit is much smaller compared to a commercial or industrial HVAC system as it needs to cool or heat a much smaller, more confined space.

2. The Institutional and Commercial Construction Sector

This crucial construction category includes the following:

- Schools

- Medical Facilities (hospitals, testing centers, etc.)

- Sports Arenas and Stadiums

- Prisons

- Retail Stores

- Shopping Centers

- Skyscrapers

This construction type includes the building, maintenance, and eventual or potential upgrades and modifications. Typically, institutional and commercial buildings in service for decades may be commissioned for upgrades and modernizations. This is still part of the institutional and commercial construction sector.

Work in this sector may be commissioned by private companies, public entities, local or state governments, and private investors. However, projects, including schools, medical facilities, and sports arenas, are often planned, managed, and paid for by a mixture of government and private or public entities.

Institutional and Commercial HVAC: Institutional and commercial buildings used by the public (schools, airports, hospitals, prisons, recreation centers, etc.) bring unique HVAC challenges since each construction comes with specific ventilation, cooling, and heating requirements. This often demands manufacturers and contractors to develop specific solutions, inventing new parts and equipment when needed.

3. The Specialized Industrial Construction Sector

This construction sector typically involves highly-specialized and technologically more advanced structures than the typical residential, commercial, or institutional construction. Projects classified as specialized industrial construction may include building structures that deal with:

- Chemical Production

- Medical (infectious diseases, virus research, biological testing, etc.)

- Power Generation (oil refineries, nuclear plants, steel mills, etc.)

- Tech

- Aerospace

Funding and executing these project types typically falls to the industry or field seeking the building or structure and may lean heavily on for-profit companies, investment firms, and corporations.

Specialized Industrial HVAC: These HVAC systems are highly challenged to ensure the correct operation of equipment and machinery that must operate in specific environmental conditions (certain industrial processes, like welding, produces considerable heat that must be disposed of, while other processes may produce harmful, airborne substances which must be contained).

4. The Infrastructure and Heavy Construction Sector

Heavy and infrastructure construction includes adding roads, railways, or communication towers to areas surrounding existing structures. Infrastructure and heavy construction are typically done to serve public interest/needs and are mostly funded by private corporations and governmental agencies. Some of these construction projects may include:

- Highways

- Tunnels

- Transit Systems

- Aviation

- Bridges and Overpasses

- Pipelines and Waste Management

- Telecommunications

Infrastructure construction includes the stations and support facilities that operate transit centers and serve the general public.

Note: This type of construction is typically executed from spring through late fall. During the winter months, other projects are undertaken until springtime, when this construction work resumes.

Infrastructure and Heavy Construction HVAC: Buildings in this construction sector are typically heated through an assortment of heat pumps using air or water. Cooling systems (chillers with air-handling equipment) can be two-pipe or four-pipe and must keep large areas with many people properly ventilated and conditioned.

The Major Construction Sectors

In this article, you discovered essential information about the 4 sectors of construction and each sector’s HVAC needs.

Knowing more about the different construction sectors will help you better comprehend your construction work and how heating, air conditioning, and ventilation requirements can vary.

Not knowing how the construction sectors differ can leave you unprepared when your expertise, input, and suggestions may be needed.

Sources:

digital.library.unt.edu/ark:/67531/metadc40151/m1/1/high_res_d/R41806_2011May03.pdf

esc.edu/media/academic-affairs/harry-vanarsdale/hvacls-publications/Construction-Industry-Fact-Book.pdf

goconstruct.org/why-choose-construction/what-is-construction/

intechopen.com/chapters/62059

wbdg.org/resources/high-performance-hvac